Introduction

Understanding Traction Elevator Basics

Traction elevators rely on a series of cables and pulleys to lift and lower the cab, making them a fascinating feat of engineering. Unlike hydraulic elevators, which use fluid pressure to move the cab, traction lifts are often more efficient and can travel greater distances without sacrificing speed or comfort. Understanding how do traction lifts work helps clarify why they are becoming increasingly popular in modern buildings.

Benefits of Traction Elevators Over Hydraulic

One major question that arises is: which is better, a hydraulic or traction elevator? While both systems have their merits, traction elevators generally offer advantages in terms of energy efficiency and speed. Additionally, one significant disadvantage of a hydraulic elevator is its reliance on oil-based fluids, which can lead to environmental concerns and maintenance issues over time.

Cost-Effectiveness of Traction Solutions

When evaluating cost-effectiveness between traction vs. hydraulic elevators, initial installation costs may vary; however, long-term savings often favor traction systems due to lower energy consumption and reduced maintenance requirements. The question does arise: does a traction elevator need a machine room? Interestingly enough, advancements in technology have led to machine-room-less designs that save valuable building space while still delivering superior performance. Ultimately, understanding what is the life expectancy of a traction elevator—often exceeding 20 years—can further illustrate their value as an investment in reliable vertical transportation.

The Mechanics Behind Traction Elevators

Understanding how traction elevators operate is essential for anyone considering their installation or maintenance. These elevators are powered by a system of cables, pulleys, and a counterweight that work together to lift and lower the elevator car smoothly. This mechanism not only enhances efficiency but also allows for greater speed compared to hydraulic systems.

How Do Traction Lifts Work?

So, how do traction lifts work? At the heart of the system is an electric motor that drives a sheave (a large wheel) around which steel cables are looped. As the motor turns the sheave, it either raises or lowers the elevator car by adjusting the tension in the cables, allowing for smooth vertical travel—making one wonder: which is better, a hydraulic or traction elevator? While hydraulic elevators rely on fluid pressure to move their cars, traction systems offer faster speeds and more energy efficiency.

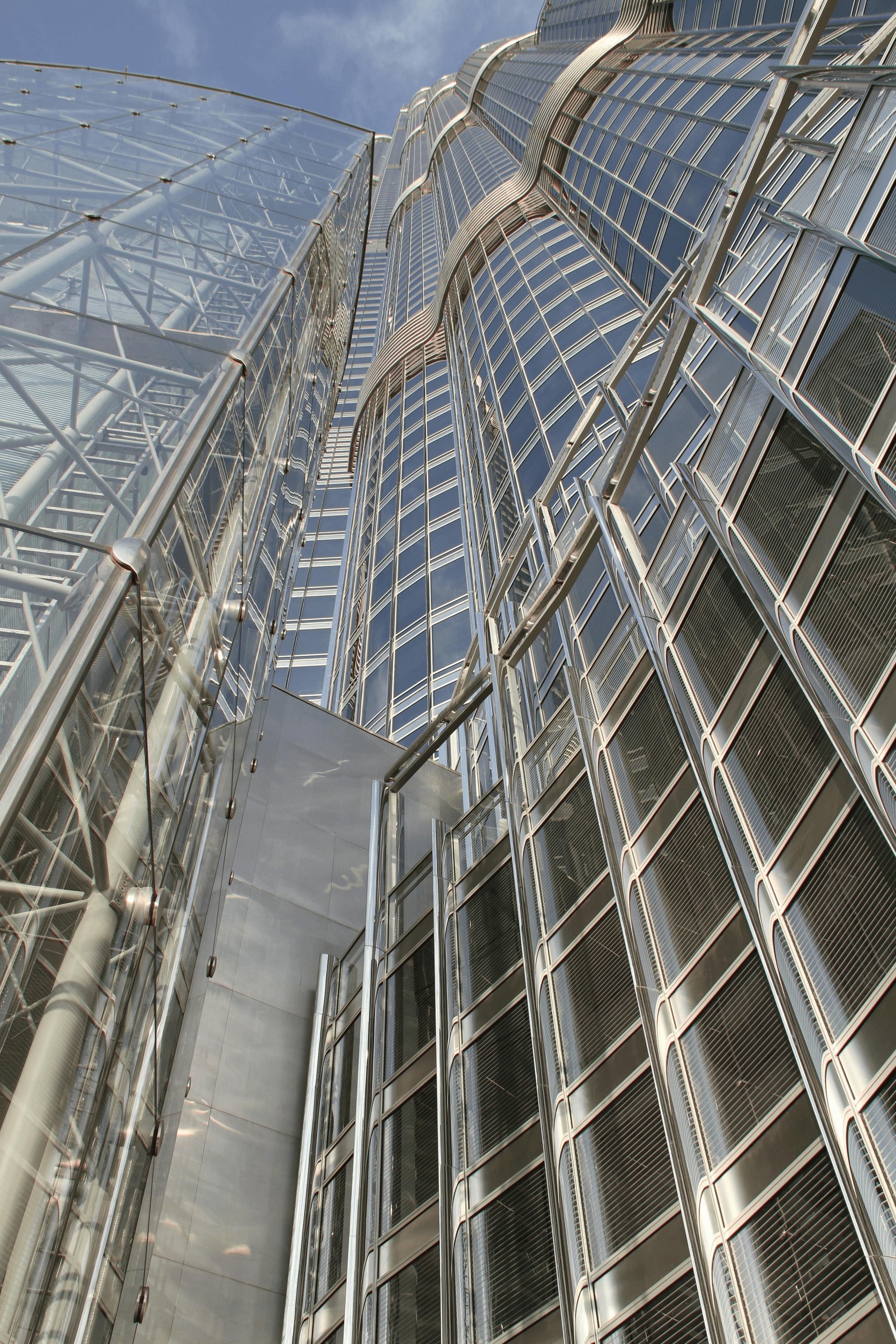

In addition to their operational mechanics, traction elevators excel in design flexibility due to their compact machinery requirements. They can be installed in various building configurations without needing extensive modifications to existing structures. This adaptability makes them particularly appealing in urban settings where space is at a premium.

The Components of Traction Elevators

The main components of traction elevators include the hoisting machine, sheaves, ropes, and counterweights—all working in harmony to ensure seamless operation. The hoisting machine houses an electric motor that drives the sheave; this component is crucial because it determines how efficiently power is transmitted to lift loads. Additionally, steel ropes connect to both the elevator car and counterweight; this setup balances weight distribution and reduces energy consumption.

Another significant aspect lies in whether a traction elevator needs a machine room; many modern designs incorporate machine-room-less (MRL) technology that eliminates this requirement altogether. This innovation not only saves space but also simplifies installation processes in buildings where every square foot counts. With fewer components taking up valuable real estate within a building's structure, architects can explore creative design options.

Safety Features of Traction Systems

Safety features play an integral role in ensuring that traction systems operate reliably and securely—after all, nobody wants an unexpected detour while riding up 20 floors! Most traction elevators are equipped with multiple safety mechanisms such as overspeed governors that detect if an elevator is moving too quickly and automatically engage brakes if necessary. Additionally, they feature door sensors that prevent closing when someone or something obstructs them.

Furthermore, understanding what is the life expectancy of a traction elevator can help owners plan for long-term maintenance costs effectively. Generally speaking, these systems can last anywhere from 20 to 30 years with proper upkeep—a lifespan significantly longer than many hydraulic counterparts due largely to reduced wear on components like pumps and hoses found in hydraulic models (which often have shorter lifespans).

In conclusion, while evaluating options between Traction vs. Hydraulic Elevators may seem daunting at first glance due to varying mechanics involved; knowing how each system operates provides clarity on which solution best suits your needs!

Cost Analysis: Traction vs. Hydraulic Elevators

Which is Better, a Hydraulic or Traction Elevator?

The debate over which is better—a hydraulic or traction elevator—often hinges on specific needs and building designs. Traction elevators utilize a system of pulleys and cables powered by an electric motor, making them more efficient for taller buildings compared to their hydraulic counterparts, which rely on fluid pressure for movement. If your building reaches several stories high, traction lifts not only save energy but also offer smoother rides and faster speeds.

Another factor to consider in this comparison is space efficiency. Does a traction elevator need a machine room? The answer may surprise you; modern innovations have led to machine-room-less (MRL) designs that provide the benefits of traction without requiring additional space for machinery. This flexibility makes them ideal for urban environments where every square foot counts.

Initial Costs vs. Long-term Savings

When evaluating initial costs versus long-term savings between traction vs. hydraulic elevators, it's essential to look beyond just the sticker price. While hydraulic systems might have lower upfront costs due to simpler installation processes, they can lead to higher operating expenses over time due to increased energy consumption and maintenance needs. In contrast, although traction elevators may require a larger initial investment, their efficiency often results in significant savings in energy bills and reduced wear-and-tear costs.

Moreover, the life expectancy of a traction elevator tends to be longer than that of hydraulic systems—often exceeding 25 years with proper maintenance compared to about 15-20 years for hydraulics. This longevity means fewer replacements are needed over time, further enhancing cost-effectiveness in the long run.

Maintenance Considerations for Both Types

Maintenance considerations play a crucial role when comparing these two types of elevators as well; each has its own quirks that can affect operational costs and downtime frequency. Hydraulic elevators typically require more frequent servicing because they depend on oil-based fluids that can leak or degrade over time—what is a disadvantage of a hydraulic elevator? Higher maintenance demands can lead to unexpected expenses if not managed properly.

On the other hand, while traction elevators generally have lower maintenance requirements due to their mechanical design being less prone to failure from leaks or fluid issues, they still require regular inspections and updates on components like cables and pulleys—especially since understanding how do traction lifts work involves recognizing their reliance on precise mechanics for safety and performance longevity.

In conclusion, while both options have unique advantages depending on usage scenarios and building specifications, many find that investing in a well-maintained traction elevator pays off through energy efficiency and longevity in the grand scheme of vertical transportation solutions.

Space Requirements and Design Flexibility

Does a Traction Elevator Need a Machine Room?

One common question is, Does a traction elevator need a machine room? Traditionally, traction elevators required dedicated machine rooms located above the shaft to house the machinery that controls the lift. However, modern innovations have led to machine-room-less (MRL) designs that integrate the machinery within the elevator shaft itself, making them more space-efficient and ideal for buildings with limited overhead space.

This shift in design means that many urban buildings can now accommodate traction elevators without sacrificing valuable square footage. By eliminating the need for a separate machine room, developers can maximize usable space in their structures while still benefiting from the efficiency of traction systems. Overall, this flexibility makes traction elevators an appealing choice for various architectural styles.

Design Innovations in Traction Elevators

The evolution of technology has paved the way for exciting design innovations in traction elevators. Manufacturers are constantly looking for ways to enhance performance while minimizing their footprint—think sleek designs with advanced control systems that improve energy efficiency and user experience. These innovations not only optimize how do traction lifts work but also ensure they meet modern aesthetic standards.

For instance, some modern traction elevators feature regenerative drives that capture energy during descent and feed it back into the building's electrical system. This not only reduces energy costs but also aligns with sustainability goals increasingly prioritized by urban planners and architects alike. As such, these advancements position traction elevators as not just functional but also stylish components of contemporary architecture.

Space-saving Solutions for Urban Buildings

In densely populated urban environments where every square foot counts, finding space-saving solutions becomes imperative—enter traction vs. hydraulic elevators again! Due to their design versatility and compact nature, traction elevators often emerge as the preferred option in high-rise buildings where maximizing floor area is essential. They can be installed in smaller shafts compared to hydraulic models while still offering impressive lifting capabilities.

Moreover, innovative designs like double-decker or multi-car configurations allow multiple cabins to operate within one shaft—further enhancing efficiency without requiring additional real estate on each floor level. This adaptability makes them particularly suitable for mixed-use developments where both residential and commercial spaces coexist in tight quarters. Ultimately, leveraging these space-saving solutions ensures that your building remains functional without sacrificing aesthetics or efficiency.

Longevity and Reliability of Traction Elevators

What is the Life Expectancy of a Traction Elevator?

So, what is the life expectancy of a traction elevator? Typically, these systems can last anywhere from 20 to 30 years or even longer with proper maintenance. Unlike hydraulic elevators, which may face more wear due to fluid leaks and other issues, traction elevators' mechanical components tend to be more resilient over time.

Factors Affecting Elevator Lifespan

Several factors can affect the lifespan of your traction elevator. Regular maintenance is key; neglecting this aspect can lead to premature wear and tear, regardless of whether you have a hydraulic or traction elevator system. Additionally, environmental conditions such as humidity levels and temperature fluctuations can impact how well the components function over time.

Real-world Examples of Long-lasting Systems

There are numerous real-world examples showcasing the longevity of traction elevators. For instance, some historic buildings still operate their original traction systems installed over 50 years ago! These cases highlight not only the durability but also how well-engineered systems can stand the test of time when cared for properly.

Common Misconceptions About Traction Elevators

When it comes to vertical transportation, traction elevators often face their fair share of misconceptions, especially when compared to hydraulic elevators. One common question that arises is: Which is better, a hydraulic or traction elevator? While both types have their merits, many people overlook the advantages of traction systems. Traction elevators are generally more efficient and offer better performance over long distances, making them a popular choice for taller buildings.

What is a Disadvantage of a Hydraulic Elevator?

One significant disadvantage of a hydraulic elevator lies in its space requirements and installation costs. Hydraulic systems typically require a machine room and additional space for the hydraulic pump and fluid reservoir, which can be an issue in urban settings where every square foot counts. Moreover, they are less energy-efficient compared to traction elevators; this inefficiency can lead to higher operational costs over time.

Breaking Down Traction Elevators Myths

There are several myths surrounding traction elevators that can cloud judgment when selecting the right system for your building. For instance, some believe that traction lifts are noisy or require extensive maintenance; however, modern designs incorporate advanced technology that minimizes noise and enhances reliability. Additionally, people often wonder: Does a traction elevator need a machine room? The answer may surprise you—many newer models utilize machine-room-less (MRL) designs that save valuable space while still offering outstanding performance.

Clarifying Customer Concerns

Customer concerns about traction vs. hydraulic elevators often stem from misunderstandings regarding lifespan and maintenance needs. Many potential users ask: What is the life expectancy of a traction elevator? Generally speaking, these systems can last 20-30 years with proper care—far exceeding many hydraulic options available today. By addressing these common misconceptions head-on and providing clear information about how do traction lifts work, customers can make informed decisions tailored to their specific needs.

Conclusion

In the grand scheme of vertical transportation, choosing the right elevator for your building can feel like a daunting task. With options like traction elevators and hydraulic elevators, it’s essential to weigh the pros and cons carefully. Ultimately, understanding your specific needs—such as space limitations, expected traffic volume, and budget—will guide you towards the best choice.

Choosing the Right Elevator for Your Building

When pondering which is better, a hydraulic or traction elevator? it’s crucial to consider factors such as building height and usage frequency. Traction elevators are often favored in mid-rise to high-rise buildings due to their efficiency and speed, while hydraulic elevators may be more suitable for low-rise applications where space is at a premium.

Additionally, you might wonder: does a traction elevator need a machine room? The answer is often no; modern designs allow for machine-room-less (MRL) solutions that save valuable building space. By evaluating these elements carefully, you can make an informed decision that aligns with your building's unique requirements.

Enhancing Efficiency with Traction Elevators

Traction elevators stand out when it comes to energy efficiency and operational performance. They utilize an intricate system of pulleys and cables that significantly reduce energy consumption compared to hydraulic systems. In environments where sustainability is paramount, opting for traction vs. hydraulic elevators can lead to lower utility bills over time.

Moreover, understanding how do traction lifts work helps in appreciating their advantages fully; they provide smooth rides without the delay associated with hydraulic systems' fluid dynamics. This efficiency not only enhances user experience but also contributes positively to overall building management strategies.

The Future of Vertical Transportation Solutions

As technology evolves, so does the future of vertical transportation solutions like traction elevators. Innovations are on the horizon that promise even greater energy savings and smarter operational capabilities through IoT integration and advanced monitoring systems. With questions such as what is the life expectancy of a traction elevator becoming more relevant than ever, it’s clear that investing in these systems yields long-term benefits.

Furthermore, addressing common concerns—like what is a disadvantage of a hydraulic elevator?—can help potential buyers understand why traction offers superior longevity and lower maintenance costs in many scenarios. As we look ahead, embracing these advancements will ensure that our buildings remain efficient hubs for movement both now and in years to come.