Introduction

When it comes to moving heavy loads within a building, the freight elevator is an essential piece of equipment. Whether it's for transporting goods in a warehouse or materials in a construction site, understanding the functionality and benefits of a fully loaded slow-moving freight elevator is crucial. Additionally, knowing the cost implications of installing and maintaining such an elevator is key to making informed decisions.

Understanding the Freight Elevator

The term freight elevator refers to a type of elevator specifically designed for transporting heavy goods or materials. Unlike regular passenger elevators, freight elevators are built to withstand heavier loads and are equipped with features that cater to industrial or commercial settings.

The Advantages of a Fully Loaded Freight Elevator

A fully loaded slow-moving freight elevator offers several advantages, including efficient transportation of heavy items without causing strain on the machinery or compromising safety. This type of elevator ensures that large loads can be moved smoothly and securely within a building, contributing to overall productivity and operational efficiency.

How Much Does a Freight Elevator Cost?

The cost of installing and maintaining a freight elevator varies depending on factors such as size, capacity, speed, and additional features required for specific applications. It's important to consider both the initial investment and long-term expenses associated with owning and operating a freight elevator in order to make an informed financial decision.

What is a Fully Loaded Slow Moving Freight Elevator?

A fully loaded slow moving freight elevator is designed to transport heavy loads at a controlled pace, ensuring safety and efficiency in the movement of goods within a building. With Schmidt's Freight Elevator, you can expect robust construction and advanced technology that guarantees smooth and reliable operation.

Exploring the Features of Schmidt's Freight Elevator

Schmidt's Freight Elevator is not only designed to handle heavy cargo with its sturdy platform and reinforced walls, but it also prioritizes the safety of delicate items. The state-of-the-art control systems allow for precise speed adjustment, ensuring a smooth and secure transportation process. This means that even fragile or valuable items can be transported without the risk of damage, making Schmidt's Freight Elevator an ideal choice for businesses that deal with a variety of goods.

The Benefits of a Slow Moving Freight Elevator

The main advantage of a slow moving freight elevator is its ability to handle large loads with utmost care, minimizing the risk of damage to goods during transit. This makes it an ideal choice for industries such as manufacturing, warehousing, and logistics where the safe movement of heavy items is crucial.

The Importance of Precise Weight Control

One key feature of Schmidt's Freight Elevator is its precise weight control mechanism, which ensures that the elevator operates within its specified load capacity at all times. This not only prevents overloading but also contributes to the longevity and reliability of the elevator system.

In addition to preventing overloading and ensuring the reliability of the elevator system, precise weight control also enhances safety for both passengers and cargo. By maintaining a consistent load capacity, the risk of accidents or malfunctions due to excessive weight is significantly reduced. This is especially crucial in commercial settings where the elevator is frequently used to transport heavy goods and equipment between floors.

The Cabin of a Small Freight Elevator

When it comes to the cabin of a small freight elevator, maximizing space is crucial for efficiency. With limited room to work with, it's important to carefully plan the layout and design to ensure that every inch is utilized effectively. By optimizing the cabin space, you can increase the capacity and productivity of your small freight elevator, making it a valuable asset for your business.

Safety measures in a small freight elevator cabin are essential to protect both workers and cargo. From non-slip flooring to secure handrails, every detail should be carefully considered to minimize the risk of accidents and ensure smooth operations. Additionally, installing safety features such as emergency stop buttons and overload sensors can provide peace of mind and prevent potential hazards in the cabin.

Customization options for small freight elevator cabins offer flexibility to tailor the design according to specific needs. Whether it's adding shelving units for organized storage or installing specialized lighting for enhanced visibility, customization allows you to create a cabin that meets your unique requirements. By working with experienced professionals, you can explore various customization options that align with your business objectives.

The Meaning of a Freight Elevator

The Role of Freight Elevators in Commercial Settings

Freight elevators are designed to handle heavy loads and provide a reliable means of transporting goods within a commercial building. With their sturdy construction and high weight capacity, these elevators are indispensable in industries that rely on the efficient movement of large items. Without them, businesses would struggle to maintain productivity and meet the demands of their customers.

Different Types of Freight Elevators

There are various types of freight elevators designed to cater to different needs within commercial settings. From fully loaded slow moving freight elevators for heavy-duty industrial applications to small freight elevators with customized cabin options for limited space environments, there is a wide range of choices available to suit specific requirements.

In addition to the traditional types of freight elevators, there are also modern, energy-efficient options available that are designed to reduce environmental impact and operating costs. These eco-friendly freight elevators utilize advanced technology and energy-saving features to provide a more sustainable solution for transporting goods within commercial buildings. With a focus on reducing energy consumption and minimizing carbon footprint, these innovative freight elevators offer a greener alternative for businesses looking to enhance their sustainability efforts.

The Evolution of Freight Elevators Over Time

The evolution of freight elevators has been remarkable, with advancements in technology leading to more efficient and safer transportation of goods. From manual operation systems to automated controls and precise weight management features, freight elevators have come a long way in meeting the ever-changing demands of modern industries.

Factors Affecting the Cost of a Freight Elevator

When it comes to understanding the cost structure of freight elevators, it's important to consider factors such as the size and weight capacity of the elevator, the type of control system used, and any additional features or customization options. These elements all contribute to the overall cost and should be carefully evaluated when planning for a freight elevator installation.

Understanding the Cost Structure of Freight Elevators

The cost structure of a fully loaded slow moving freight elevator typically includes expenses for materials, labor, and installation. Additionally, there may be ongoing maintenance costs to consider. It's essential to work with reputable suppliers who can provide transparent pricing and detailed breakdowns of all associated expenses.

When budgeting for a freight elevator installation, it's important to consider not only the initial costs but also the long-term expenses. Ongoing maintenance costs can add up over time, so it's crucial to factor these into the budget from the start. Working with reputable suppliers who offer transparent pricing and detailed breakdowns of expenses will help ensure that there are no unexpected costs down the line. By carefully considering all aspects of the cost structure, businesses can make informed decisions about their freight elevator investments.

Budgeting for a Freight Elevator Installation

When budgeting for a freight elevator installation, it's crucial to account for all potential costs upfront. This includes not only the initial purchase and installation but also any necessary structural modifications or upgrades required to accommodate the elevator. By thoroughly assessing these expenses in advance, you can avoid unexpected financial burdens down the line.

After thoroughly assessing these expenses in advance, you can then focus on getting the best value for your investment. This includes researching different elevator models and suppliers to find the most cost-effective option without compromising on quality or safety. Additionally, consider the long-term maintenance and operational costs of the elevator to ensure that it remains a sound investment for years to come. By taking a comprehensive approach to budgeting, you can make informed decisions that benefit your business both financially and operationally.

Getting the Best Value for Your Investment

To ensure you're getting the best value for your investment in a fully loaded slow moving freight elevator, it's wise to seek out quotes from multiple suppliers and compare their offerings. Look beyond just the upfront cost and consider factors such as warranty coverage, energy efficiency, and long-term reliability. By weighing these considerations carefully, you can make an informed decision that maximizes your investment.

When comparing quotes from different suppliers, it's important to look beyond just the upfront cost. Consider factors such as warranty coverage, which can provide peace of mind and potentially save you money in the long run. Additionally, energy efficiency is a key consideration that can lead to cost savings over time. By carefully weighing these factors, you can make an informed decision that maximizes the value of your investment in a freight elevator.

Conclusion

When it comes to choosing the right freight elevator for your needs, it's important to consider factors such as weight capacity, speed, and customization options. Whether you need a fully loaded slow moving freight elevator for heavy-duty industrial use or a small freight elevator for limited space, there are plenty of options available to meet your specific requirements. By maximizing efficiency with your freight elevator, you can ensure smooth operations and increased productivity in your business. And with future innovations in freight elevator technology on the horizon, the possibilities for even greater efficiency and functionality are endless.

Choosing the Right Freight Elevator for Your Needs

When selecting a freight elevator, it's crucial to carefully assess your specific needs and requirements. Whether you're looking for a fully loaded slow moving freight elevator or a smaller cabin design, consider factors such as weight capacity, speed, and safety features to ensure that you make the right choice for your business operations. By choosing the right freight elevator for your needs, you can optimize efficiency and streamline your logistics processes.

Maximizing Efficiency with Your Freight Elevator

To maximize efficiency with your freight elevator, it's essential to prioritize proper maintenance and regular inspections to ensure smooth operation at all times. Additionally, training staff on safe usage and best practices can help minimize downtime and prevent accidents in the workplace. By implementing efficient loading and unloading procedures, you can further enhance productivity while utilizing your fully loaded slow moving freight elevator or small cabin design to its fullest potential.

In addition to regular maintenance and staff training, investing in modern freight elevator technology can also significantly boost efficiency. Upgrading to a more advanced control system, for example, can help optimize the elevator's performance and minimize wait times for loading and unloading. Furthermore, exploring innovative features such as predictive maintenance tools can proactively identify potential issues before they escalate, ultimately reducing downtime and repair costs. By staying abreast of the latest advancements in freight elevator technology, businesses can stay ahead of the curve and maximize their operational efficiency.

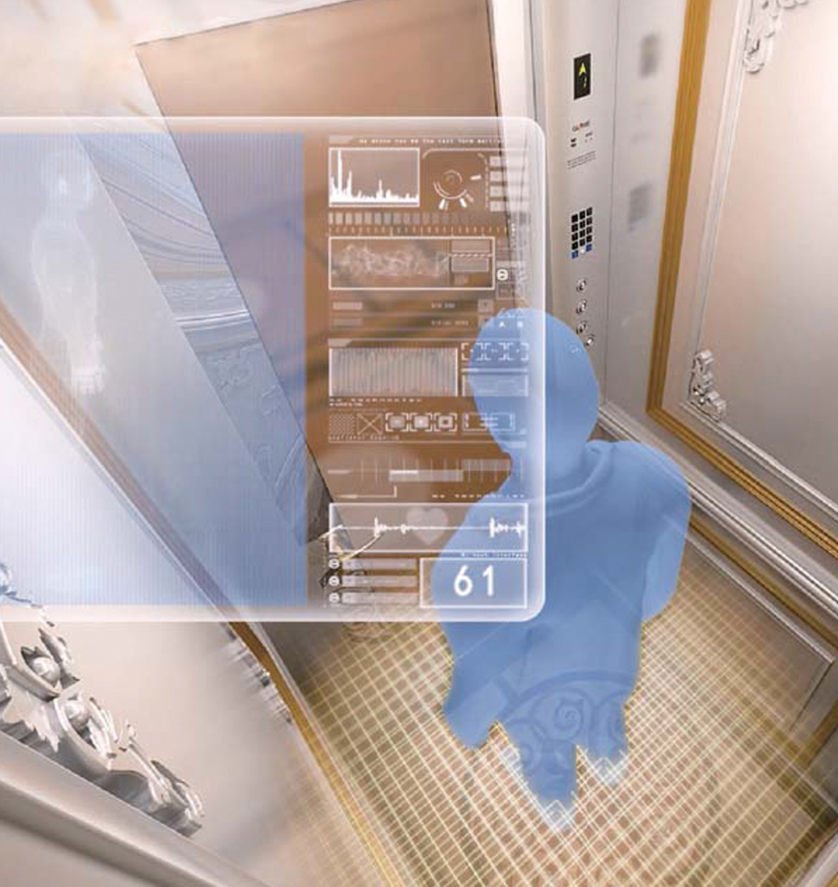

Future Innovations in Freight Elevator Technology

As technology continues to advance at a rapid pace, we can expect exciting innovations in the realm of freight elevators. From improved energy efficiency to enhanced safety features and advanced control systems, future developments promise even greater functionality and performance. Keep an eye out for cutting-edge advancements that could revolutionize the way we think about fully loaded slow moving freight elevators and small cabin designs in commercial settings.

With the rise of automation and artificial intelligence, we can expect to see freight elevators equipped with advanced self-diagnostic systems that can detect and address maintenance issues before they become major problems. This will not only reduce downtime and repair costs but also enhance the overall reliability of freight elevator systems. Additionally, the integration of IoT (Internet of Things) technology will enable real-time monitoring and data analysis, allowing for predictive maintenance and proactive management of elevator performance.